1 With the fretboard you can either buy a pre-shaped pre-slotted from wood and part dealers, or you can make your own. You will find more information on pre-shaped and pre-slotted pieces on the wood’s pages.

2 With your own the measurements should be made from a very dense hardwood. Make sure that it is plained and sanded to exactly 3/16” along the full length. Also check for any cracking. The fretboard must be cut exactly as measured and must folly these guidelines:

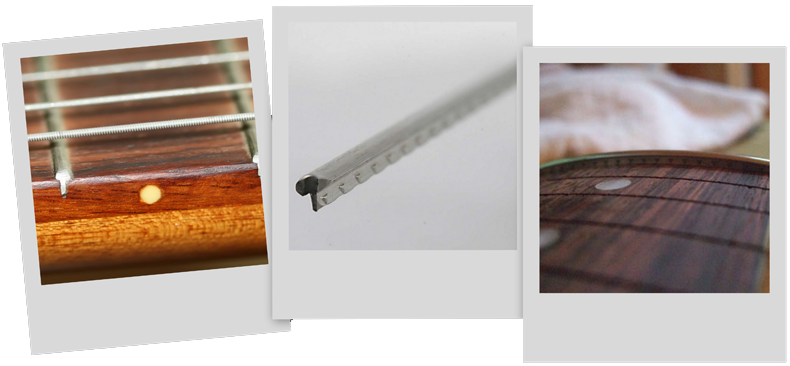

- The fretslots must be .023” wide.

- They must be slightly deeper then the tang on the fretwire you chose to use (generally about 2/3rds of the way through the board).

- For a 25 and 3/4” neck use exactly these distances (for other neck lengths I suggest buying the book formally mentioned).

- Fret spaces start at the peghead and are in inches.

1.445 • 1.364 • 1.287 • 1.215 • 1.147 • 1.082 • 1.021 • 0.964 • 0.910 • 0.859 • 0.811 • 0.765 • 0.722 • 0.682 • 0.643 • 0.607 • 0.573 • 0.541 • 0.510 • 0.482 • 0.455 • 0.430

3 After you have accurately made these cuts you should trace the outline of the fretboard onto yours and cut it out. Then you need to attach it to the neck. This is best done by drilling two small holes into the neck and putting a small round-head brand into them. Then position the fretboard into place and tape it lightly to make 2 indents from the brands and drill a small hollow in those places so the heads fit good. Then glue it into place and secure it using C-clamps.

4 If you wish to do inlays or bindings on your neck buy the book, or find other sources.

5 At this point (or after doing inlays) you need to arch the fretbaord. An exceptable arch can be created by using a belt sander and carefully rock the neck, make sure to remove equal amounts. Then you need to insert the frets. Do this by cutting each fret a little long and remove some of the tang from each end. Then hammer against a steel or brass block to get them in place. Then use a fine tooth file to file off the edges. Lastly finish shaping the neck staring with a rasp and ending on a 200 grit sandpaper (be sure not to round any of the pegheads corners or edges).